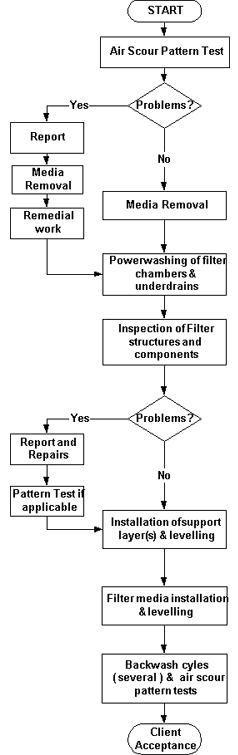

Media Placement - Typical Process

Media Placement -Typical Process

Typical process in filter media placement project is shown in the diagram opposite. Please click on the stages of interest in the diagram for more information on the actual process involved.

- 1. Air Scour pattern tests conducted to ensure that the current filter plant is operating normally so that any subsequent backwashes and pattern tests can be conducted

- 2. Any problems identified in the air scour tests are investigated and a report provided detailing causes and recommended remedial work together with any anticipated costs associated with the repairs.

- 3. Existing media is removed using appropriate plant equipment ( dry or wet vacuum tankers ) and disposed of according to appropriate legislation and industry recommendations.

- 4. Powerwashing existing structures removes slime build up for any subsequent inspections.

- 5. After washing both the filter walls / structures and filter components are inspected to determine their status. Endoscopic inspections ( if required) may be carried out at this point to determine the status of lateral pipework/plenum chambers.

- 6. Any problems e.g. damaged nozzles, wall structure problems, sealant joint integrity etc. are identified and a report submitted to the client for their information. The client will be encouraged to inspect any remedial works carried out on their behalf.

- 7. Support layer(s) are installed using approved grades of media to ensure proper operation after commissioning. Support layer(s) are levelled off correctly to minimise localised problem areas in operation. Deformations in the support layer(s) can lead to early refurbishment requirements and lower efficiency in backwash cycles.

- 8. Filter media ( filter sand, anthracite ) is now placed carefully to prevent distortion to the support layers. Media grade(s) are carefully selected to give optimum filter efficiencies.

- 9. Filter is now backwashed ( normally twice ) to remove any fine particles of filter media which may present in any new filter media. Backwashing also forms part of the customer acceptance and gives confidence in the overall operation of the plant.

Summary of the whole project is supplied to the client for their information and acceptance